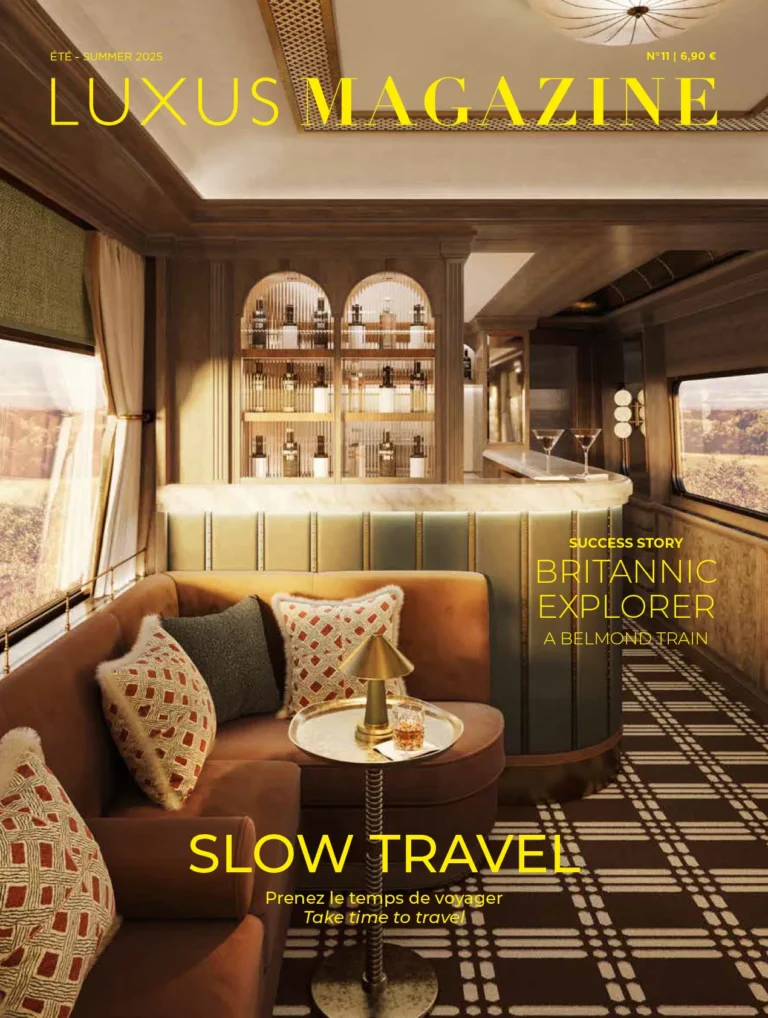

Haute Maroquinerie manufacturing in France is not only perpetuated by Hermès and Louis Vuitton. Smaller players, such as Longchamp, continue to keep leather craftsmanship alive, for a more accessible luxury.

A Made in France luxury bag….The nec plus ultra.

While many fashion houses, including luxury brands, now outsource their collections abroad, Haute Maroquinerie made in France has not said its last word.

Know-how of excellence

The spectrum is broad, ranging from hard luxury, sometimes on stratospheric price scales, to soft luxury, more accessible. And while Hermès and Louis Vuitton communicate extensively about their French workshops, it’s also possible to treat yourself to more affordable, beautifully crafted models made in France, such as a Lonchamp women’s leather handbag. Founded in 1948, Lonchamp has preserved its savoir-faire while creating collections that are in tune with the times at “reasonable” prices. Even if Longchamp is also part of the closed circle of the Colbert Committee, the French luxury goods association, along with Hermès and Louis Vuitton.

For purists with sufficient means (and sometimes the necessary patience), buying a Hermès model is aguarantee of excellent French craftsmanship.

The Maison de la rue du Faubourg Saint Honoré manufactures its leather goods exclusively in its own workshops, all located in France.

For the past two decades, Hermès has been opening small-scale units of around 300 employees in various regions of France, at a rate of around one a year. The aim is to meet strong demand. To acquire the iconic Birkin and Kelly models, you have to be prepared to wait several months before they are manufactured. Even so, with some forty bag models, Hermès can quickly satisfy the impatient.

Against this backdrop, the saddlery manufacturer inaugurated its 23rd leather goods unit on September 13, in Riom, near Clermont-Ferrand.

Handcrafted model

To mark the occasion, Guillaume de Seynes, Hermès’ Managing Director in charge of the upstream division and investments, emphasized the group’s commitment to “the highest standards of quality” and to “the artisanal model that sets us apart, which we call ‘a man, a bag’”. In other words, a model is made from A to Z by the same person, apart from the cutting and machine-stitching stages, which are separate skills.

Guillaume de Seynes also recalled theHouse’s original know-how, that of harness-maker and saddler. Since the very first bag designed by Émile Hermès in 1932, all the House’s models have used the saddle-stitching technique, a two-needle seam also used to make saddles. It’s a time-consuming process, requiring fifteen to twenty hours of work depending on the model. But thanks to this process, you can be sure of their solidity and durability…

At Louis Vuitton, LVMH’s flagship company, Made in France is also a priority. Even if, unlike Hermès, Louis Vuitton has also opened workshops inother European countries, namely Spain and Italy, and in a major market for the brand, the United States.

Louis Vuitton: two inaugurations in Loir et Cher in 2022

The last two inaugurations of the Maison’s French leather goods production sites, dedicated in particular to exotic skins, took place at the beginning of 2022 in Azé and Vendôme, in the Loir-et-Cher region.

After an exceptional year in 2021, Louis Vuitton’s aim was to meet the exponential demand for exotic leather bags from China and South Korea, as Michael Burke, the company’s CEO, explained at the time.

This brought Louis Vuitton’s industrial park to 18 workshops in France, employing 4,800 people at the time.

But the company still planned to recruit a thousand more craftsmen by the end of 2024, notably through the opening of two new workshops in France, in Charmes sur l’Herbasse, near Valence, and Beaulieu-sur-Layon (Maine-et-Loire).

At the inauguration of the two new units in the Loir et Cher region, Bernard Arnault reminded us that his “craftsmen were making products on the waiting list”.

Nor are these craftsmen trained in the blink of an eye. According to Valérie Dubois, production manager for Louis Vuitton leather goods in France, it takes between a year and a year and a half to train employees in the fundamentals of their trade and get them up and running.

Valuable expertise at Longchamp

The family-owned Maison Longchamp, queen of the iconic Pliage bag, has also deployed several manufacturing units since its creation in 1948. The latest of these came on stream in 2018, in Pouzauges, Vendée.

Longchamp now has six production sites in Western France, in Mayenne, Vendée, Maine-et-Loire and Orne. More than 800 men and women, spread over 25 workshops, also possess invaluable expertise.

Built by four successive generations of the Cassegrain family, Longchamp’s success story is based on an essential know-how: leatherworking. Longchamp was the first to sheathe pipes in supple leather, a technique that was later used to create other objects with a genuine second skin. But Longchamp didn’t rest on its laurels. It has continued to bring its leather expertise to life in collections that are constantly renewed to adapt to contemporary trends.

One example is the “Le Pliage” bag. It was invented in the early 70s by Philippe Cassegrain, after a trip to Japan. Inspired by origami, the Nipponese art of creating mini-sculptures by folding paper, he created the first prototype of a nylon canvas bag with leather handles, which could also be folded to the size of an envelope to fit easily into luggage.

World’s best-selling bag

By the early ’90s, the perennial codes of the bag had been established: a trapezoidal shape with a flap, two spiked handles, two small leather ears and a snap fastener on the back…

Nevertheless, this model, which has become the House’s absolute best seller and the world’s best-selling bag, has never ceased to reinvent itself, multiplying formats and materials. This has been particularly true since 1995, thanks to the creativity of Artistic Director Sophie Delafontaine and collaborations with outside talents such as designers Jeremy Scott and Mary Katrantzou, and illustrator Robert Wagt.

Among its many variants, the most luxurious is undoubtedly “Le Pliage Cuir”, introduced in 2012, which folds just as well as the original nylon version.

But lovers of fine leather goods can also turn to other more recent Longchamp creations, such as the latest addition to its family, “Le Foulonné”, in cowhide. Adopting the original shape of a trapezium, it transforms easily into a tote bag thanks to a simple snap button.

To maintain its affordable luxury positioning, Longchamp has expanded its production base beyond France, with two production sites abroad, in Tunisia and Mauritius, and partner workshops in France, China, Romania and Morocco. However, the design and creation of its models remain based in France. And the brand assures that all manufacturing steps are carried out identically in all its workshops, wherever they are located…

Read also > 5 new suitcases perfect for travelling

Featured Photo: © Longchamp